1. Belt Filter Press

– Definition: A belt filter press uses a series of belts to squeeze water out of sludge, forming a thickened sludge cake.

– Design Characteristics: Sludge is fed between two belts, and as it passes through rollers, pressure is applied, squeezing out water. The resulting cake is then removed.

– Advantages: Continuous operation, high efficiency, and suitable for various sludge types.

– Applications: Municipal and industrial wastewater treatment plants.

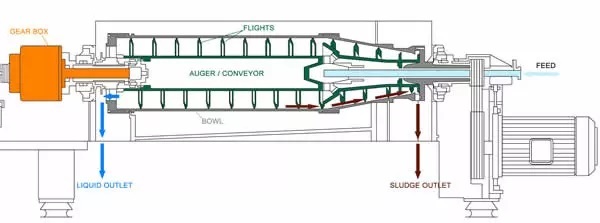

– Definition: Centrifugation uses centrifugal force to separate water from sludge by rapidly rotating a drum or bowl.

– Design Characteristics: Sludge is introduced into a rotating drum, and centrifugal force pushes water to the drum’s periphery, allowing the solids to be collected.

– Advantages: Fast operation, high solids capture efficiency, and versatility in handling different sludge types.

– Applications: Municipal and industrial wastewater treatment, as well as in other industries like food processing.

– Definition: A filter press uses a series of plates and frames to mechanically compress sludge and remove water.

– Design Characteristics: Sludge is pumped into chambers formed by plates and frames, and pressure is applied to dewater the sludge.

– Advantages: Efficient for high solids recovery, suitable for various sludge types, and can produce a dry cake.

– Applications: Municipal and industrial wastewater treatment, mining, and other industrial processes.

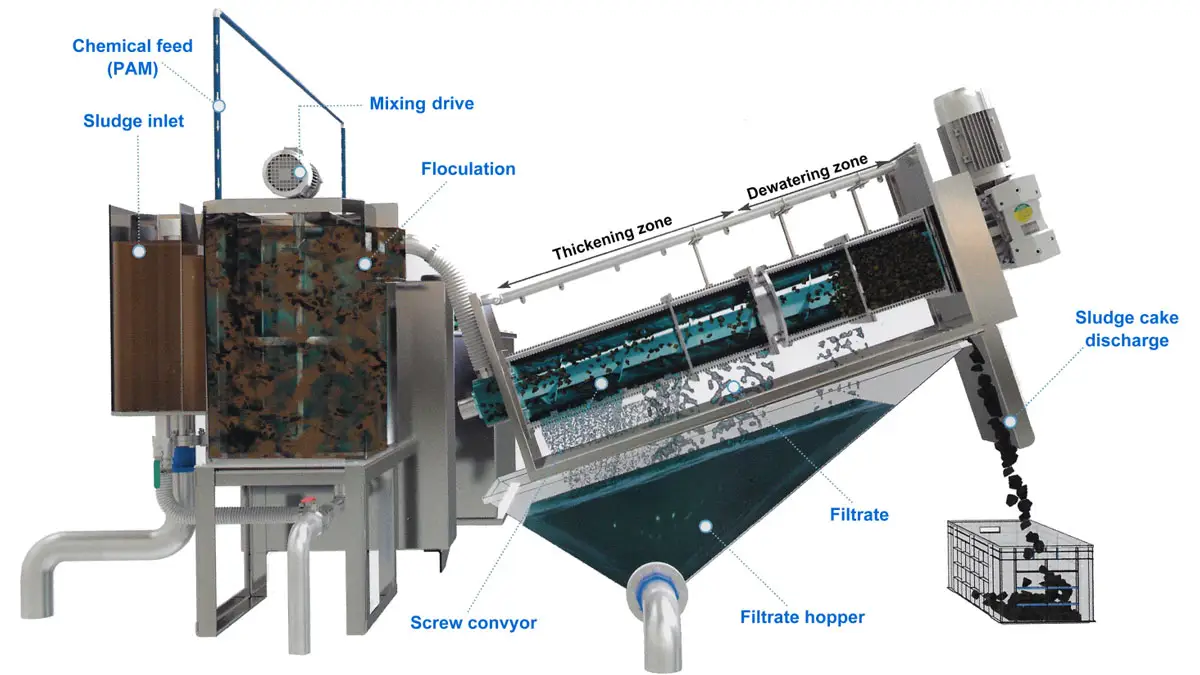

– Definition: A screw press uses a rotating screw to gradually compress and dewater sludge.

– Design Characteristics: Sludge is fed into the press, and the screw applies pressure, squeezing out water as the sludge moves through the press.

– Advantages: Continuous operation, compact design, and efficient dewatering.

– Applications: Municipal wastewater treatment, food processing, and pulp and paper industry.

Gamal AlDin Dwidar Street 1, AlHadiqah Ad Dawleyah, Nasr City, Cairo

01019689990

Tikal Water & Irrigation Systems © All Copyright 2024